American manufacturing companies with revenues between $20 million and $400 million face a critical inflection point. After decades of success built on deep manufacturing expertise and substantial capital investments in machinery, many of these companies now find themselves at a crossroads. Their rigid, highly optimized production lines that once drove profitability are becoming barriers to growth, innovation, and competitiveness.

The challenge isn't their manufacturing capability—it's their approach to

manufacturing in an increasingly digital world. To remain competitive, these successful manufacturers must fundamentally reimagine themselves: they must become software companies that happen to manufacture products, rather than manufacturing companies that use some software.

The Software-First Manufacturing Revolution

The most successful modern manufacturers have already made this transformation. Companies like Protolabs, SendCutSend, and MacroFab didn't just digitize their operations, they built their entire business models around software-driven manufacturing:

Protolabs revolutionized rapid prototyping by allowing engineers to upload 3D CAD models directly through their web portal, automatically generating quotes and production schedules without human sales intervention. This required massive investments in custom software engineering, but the payoff has been dramatic business growth as engineers gravitate toward their frictionless ordering process.

SendCutSend automated sheet metal fabrication by developing sophisticated software that can parse 2D and 3D models, automatically optimize cutting patterns, and route jobs through their production floor—all without human salespeople. What used to require extensive back-and-forth conversations now happens instantly online.

MacroFab tackled the incredibly complex world of printed circuit board manufacturing through advanced software parsing of design files. Their system is so thorough that design files can be handed directly to manufacturers without human intervention, despite PCBs being wildly complicated products that vary dramatically in size, shape, functionality, and component requirements.

These companies succeeded because they recognized a fundamental truth: in modern manufacturing, the real competitive advantage isn't just in making things — it's in the software that orchestrates, optimizes, and automates the entire process from order to delivery.

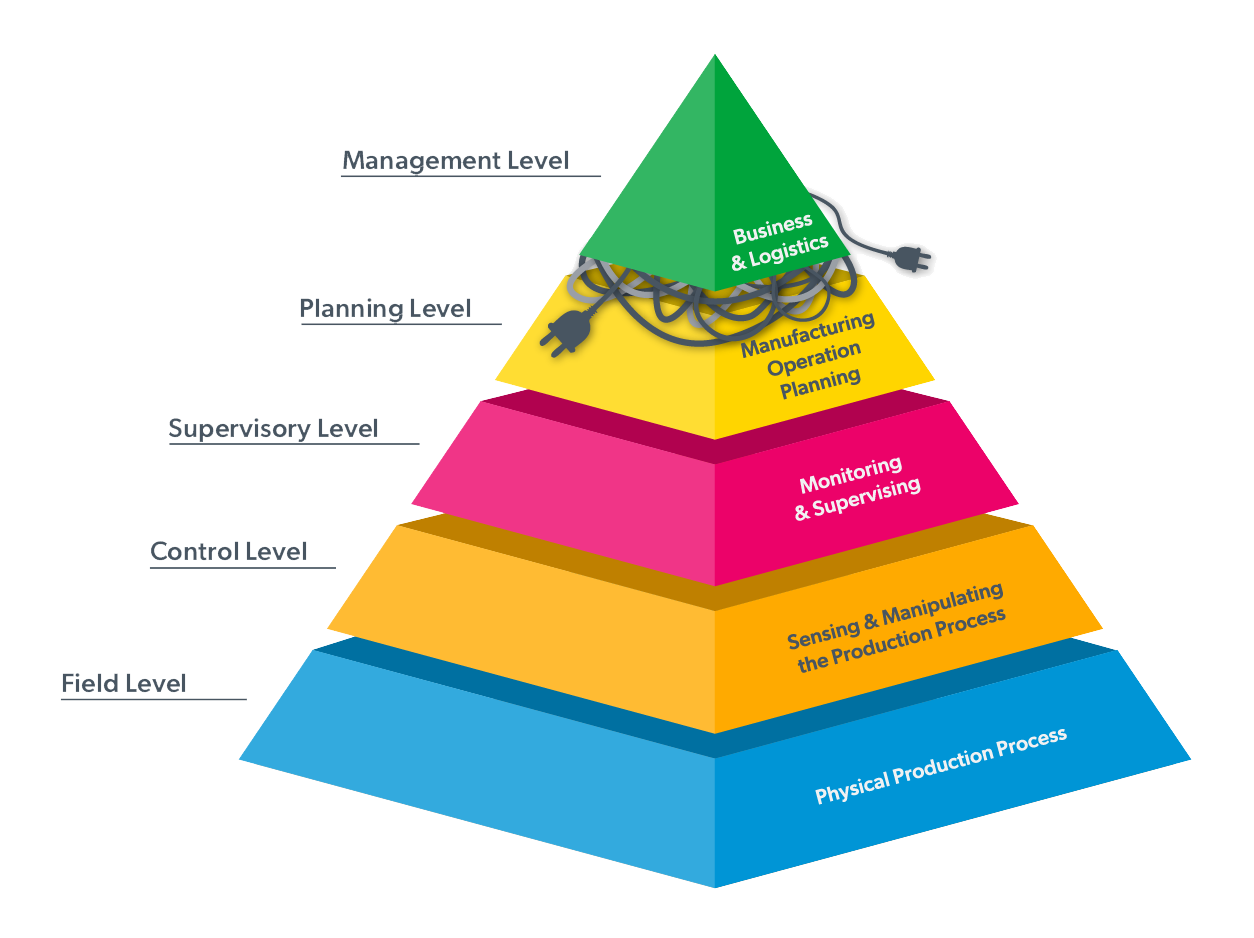

The ERP-MES Integration Challenge

Most successful manufacturing companies built their operations around Enterprise Resource Planning (ERP) systems designed to manage their core business processes: purchasing, inventory management, order processing, and financial reporting. These systems excel at managing the business side of manufacturing but struggle with real-time control and analytics of actual production processes.

Figure 1: Classic ISA-95 Pyramid Illustrating ERP-MES Integration Challenges

The problem becomes apparent when companies try to tightly integrate their manufacturing processes directly with their ERP systems. ERPs operate on business timescales—hours, days, weeks—while manufacturing operates on production timescales—seconds, minutes, cycles. This mismatch creates bottlenecks and limits the ability to implement dynamic, responsive manufacturing processes.

The Solution: Manufacturing Execution Systems

Manufacturing Execution Systems (MES) systems serve as the critical bridge between your ERP's business logic and your shop floor reality. While your ERP handles orders, inventory, and scheduling at a business level, your MES manages the real-time execution of production:

Recipe Management: MES systems understand what product is being manufactured and can feed machines the proper configuration and programming

Real-time Control: Unlike ERPs, MES systems can make split-second decisions and adjustments based on current conditions

Process Analytics: Continuous monitoring of equipment performance, worker productivity, and product quality

Traceability: Serial number tracking and historical records of how each product was manufactured

The integration challenge isn't technical—it's strategic. Companies must recognize that their ERP and MES serve different but complementary functions, with MES handling the real-time manufacturing orchestration that ERPs simply weren't designed for.

The Machine Inventory Imperative

Before any digital transformation can begin, manufacturers must conduct a comprehensive inventory of their current capabilities. This isn't just about counting machines—it's about understanding the digital transformation potential of every piece of equipment, work cell, and process on your floor.

Category 1: Modern Machines (Past 15-20 Years)

These machines represent your digital transformation foundation. They typically feature:

Network connectivity with TCP/IP support

Modern PLCs (Rockwell/Allen-Bradley, Siemens, ABB, Phoenix Contact)

Remote monitoring and control capabilities via TCP sockets, OPC-UA, Ethernet/IP, Profinet, BACnet, EtherCAT, MQTT, REST, Modbus and other SCADA technologies

Recipe-based operation support

The key advantage: these machines can often be integrated into an MES system with relatively minimal modification. However, having modern hardware isn't enough—the software on these machines must support network-based recipe management and remote operation.

Category 2: Legacy Automated Machines

These machines have some automation but lack network connectivity or software interfaces:

Legacy PLCs without network capabilities

Simple interface controls (switches, relays, lights)

Closed-loop process control without network integration

Often designed in the 1990s or early 2000s

These machines represent both a challenge and an opportunity. While they can't be easily integrated as-is, their control systems can typically be upgraded to modern, network-capable systems. This usually requires custom automation engineering but can be highly cost-effective compared to complete machine replacement.

Category 3: Manual and Ancient Machines

These represent either fully manual processes or machines so old that automation retrofit isn't practical:

Purely analog controls

Complete human operation requirement

Ancient automation that's beyond economic upgrade

For these processes, the decision matrix is clear: calculate the labor costs of continued manual operation versus the investment in new automated equipment. Often, collaborative six-axis robots with machine vision can automate many manual material handling and processing tasks at reasonable cost points.

Building Your Digital Manufacturing Roadmap

Once you've completed your machine inventory and categorization, you can develop a strategic roadmap for MES implementation that doesn't disrupt current operations.

Phase 1: Infrastructure & Planning

Ensure robust networking infrastructure throughout your facility

Implement proper IT security posture with VLAN segmentation for manufacturing networks

Select and implement your MES platform (cloud-based or on-premises)

Identify your first pilot machine or work cell

Phase 2: Incremental Integration

The beauty of MES implementation is that it can be done incrementally without disrupting existing workflows:

First Machine Integration: Upgrade your most suitable modern machines to connect with the MES. These machines continue doing exactly what they did before, but now they're software-connected and monitored.

Sequential Expansion: Add machines one-by-one. Each addition increases your visibility and control without requiring wholesale process changes.

Legacy System Upgrades: As budget allows, upgrade legacy machine control systems to modern, network-capable platforms.

Phase 3: Process Optimization

With multiple machines connected to your MES:

Implement advanced analytics and statistical process control

Enable dynamic job routing and scheduling

Deploy predictive maintenance capabilities

Integrate quality control and traceability systems

Overcoming Common Implementation Barriers

In this section, we'll review some common implementation barriers that leave manufacturers feeling handcuffed when it comes to modernization initiatives.

The Windows Problem

Many manufacturing companies face a specific technical challenge: their machine control computers run outdated Windows versions that IT departments can no longer support. A Windows 7 machine from 2010 may control a perfectly functional manufacturing line but represents a security and support nightmare.

Solution: Modern virtualization technology can sandbox these Windows environments, allowing you to maintain machine compatibility while meeting IT security requirements. Since most modern machine communication happens over TCP/IP networks rather than legacy hardware connections, virtual machines can often be substituted for aging physical computers.

The IT Department Challenge

IT departments often resist connecting manufacturing equipment to corporate networks, viewing them as security risks. This is a leadership and education challenge, not a technical one.

The solution is implementing a zero-trust security model with proper network segmentation. Manufacturing equipment can operate on dedicated VLANs, completely isolated from office networks while still enabling MES connectivity. Software-defined networking from vendors like Cisco and Ubiquiti makes this straightforward to implement and manage.

The Skills Gap

Many manufacturing companies lack software engineering and networking expertise. However, modern AI-powered development tools have dramatically lowered the barrier to custom software development, making it more feasible for manufacturing companies to develop internal capabilities or work effectively with software partners.

The Competitive Imperative

The manufacturers who make this digital transformation will gain substantial competitive advantages:

Operational Efficiency: Real-time monitoring and control enable dramatic improvements in Overall Equipment Effectiveness (OEE), reducing waste and increasing throughput.

Quality Control: Networked machines enable comprehensive statistical process control, ensuring consistent quality and providing complete traceability for every manufactured product.

Flexibility: Software-controlled manufacturing processes can adapt quickly to new products, custom orders, and changing market demands.

Cost Reduction: Automated scheduling, inventory management, and predictive maintenance reduce operational costs while improving reliability.

Customer Experience: Like Protolabs and SendCutSend, manufacturers can offer customers seamless ordering experiences with real-time pricing, scheduling, and tracking.

Conclusion: The Path Forward

The transformation from traditional manufacturer to software-enabled manufacturer isn't optional—it's inevitable. Companies that delay this transition will find themselves competing against increasingly efficient, flexible, and responsive competitors who have made the investment in digital manufacturing capabilities.

The good news is that this transformation can be implemented incrementally, without disrupting successful existing operations. By taking inventory of current capabilities, implementing proper networking infrastructure, and gradually integrating machines into an MES platform, manufacturers can evolve their operations while maintaining profitability.

The most successful manufacturers of the next decade will be those who recognize that their core competency isn't just making things—it's using software to make things better, faster, and more efficiently than ever before. The question isn't whether to make this transformation, but how quickly you can begin.

The future of American manufacturing belongs to companies brave enough to become software companies that happen to make physical products. The time to start that journey is now.