In manufacturing, time is money—and efficiency can make or break a business. Yet, many production floors are still bogged down by manual processes that rely on stacks of printed production orders, manual data entry, and worst of all, tribal knowledge.

While companies may have been able to skate by with inefficient processes like this in the past, the stakes are much higher in today’s hyper-competitive manufacturing landscape. Businesses that fail to optimize their workflows risk being disrupted—or even passed—by competitors who are embracing smarter, faster, and more adaptable technologies. With the demand for speed, accuracy, and agility at an all-time high, clinging to outdated processes isn’t just inefficient; it’s a liability that could cost you your edge in the market.

Many of the manufacturing companies we talk to assume that automation is out of reach due to limited IT budgets or reliance on outdated equipment they can’t afford to modernize. However, these challenges aren’t insurmountable. Building on Microsoft’s low-code Power Platform, you'd be amazed at the level of automation that can be achieved on a limited budget.

To demonstrate how this works, in this article we'll explore how low-code tools like Power Automate can be used to transform a traditional paper-based production process into a cutting-edge, fully automated system—enhancing productivity and reducing costly errors.

Understanding Common Challenges

Before we delve into any specific use cases, it’s important to acknowledge some specific technical challenges that many manufacturing companies face when it comes to building automation solutions:

Manufacturing Systems Integration (or lack thereof): Managing complex ERP or shop floor systems (e.g., MES systems) such as SAP is a common hurdle. These systems, while critical, often require significant effort to operate, with data trapped in silos and processes that are not easily streamlined. As you grow or diversify your product lines, these systems can proliferate and become even more cumbersome to manage, limiting flexibility and innovation.

Legacy Equipment: While outdated machines may still get the job done, they can be extremely difficult to work with. Most of these machines were built long before modern integration standards and can often only be controlled by proprietary desktop software applications. Their limited connectivity creates significant challenges in sharing data between systems and machines, often leaving operators to rely on manual processes such as re-entering data or referencing printed production orders. These outdated workflows not only slow down production but also increase the likelihood of errors, ultimately reducing both operational efficiency and product quality.

Shortage of Skilled Hardware Integration Specialists: Related to the legacy equipment issue, there's also a growing scarcity of professionals with expertise in low-level programming, such as C/C++, and the specialized knowledge required to develop drivers, interfaces, and software that can directly communicate with legacy hardware and industrial equipment. This talent gap makes it increasingly difficult for manufacturers to maintain, upgrade, or integrate their existing systems with modern technologies.

Solving for these types of challenges requires more than just patchwork solutions—it calls for a comprehensive platform that's capable of seamlessly integrating with both shop floor systems and legacy machines. Just as important, the platform must be capable of coordinating end-to-end processes, ensuring that data flows smoothly across systems while delivering work tasks into the hands of the right people—or machines—at precisely the right time.

Figure 1: The Tangled Web of ERP and Manufacturing Execution Systems

In the next section, we’ll explore how the Microsoft Power Platform provides all the tools we need to make this vision a reality.

Case Study: Transforming Production Order Processing

To illustrate how the Microsoft Power Platform can be used to build powerful (and yet affordable) industrial automation solutions, let’s consider a use case for a fictitious manufacturing company called the Acme Anvil Corporation.

Current State Process Analysis

Before, Acme’s production process was almost entirely manual. Production order packets were printed out from an SAP ERP system and physically carried over to individual workstations. At each station, machine operators had to read through the order and manually key in order details into ancient Windows desktop software applications provided by various equipment manufacturers.

Figure 2: Working with Proprietary Equipment Software

At the culmination of each production order task, machine operators would then log into SAP, document the results, and then mark the task as completed before moving onto the next task. Besides being slow and tedious, these manual processes were extremely error prone and would cost the company dearly if an operator accidentally made a mistake.

Over the course of the next several sections, we'll look at ways of incrementally improving this process using the Power Platform.

Developing an Integration Hub

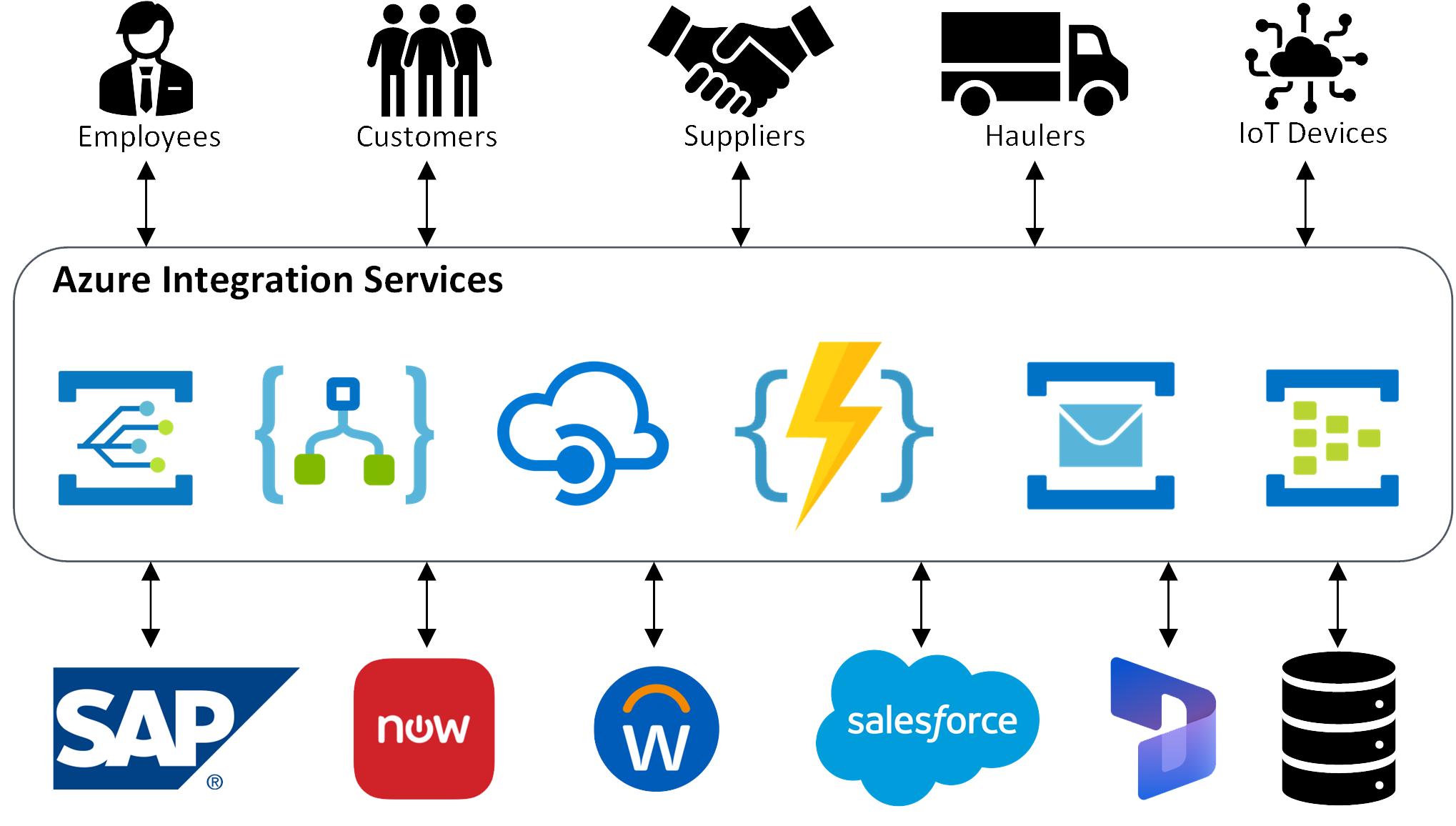

One of the biggest challenges in modernizing production workflows like this is determining how best to manage the variety of systems involved—from ERP platforms to shop floor machines and proprietary software. Developing an integration hub is a critical step toward breaking down these silos and enabling seamless data flow across the entire process. Microsoft Power Automate (as part of Microsoft's Azure cloud integration platform) provides an optimal solution for this, offering a robust, low-code platform that can connect and coordinate the various systems participating in the production process.

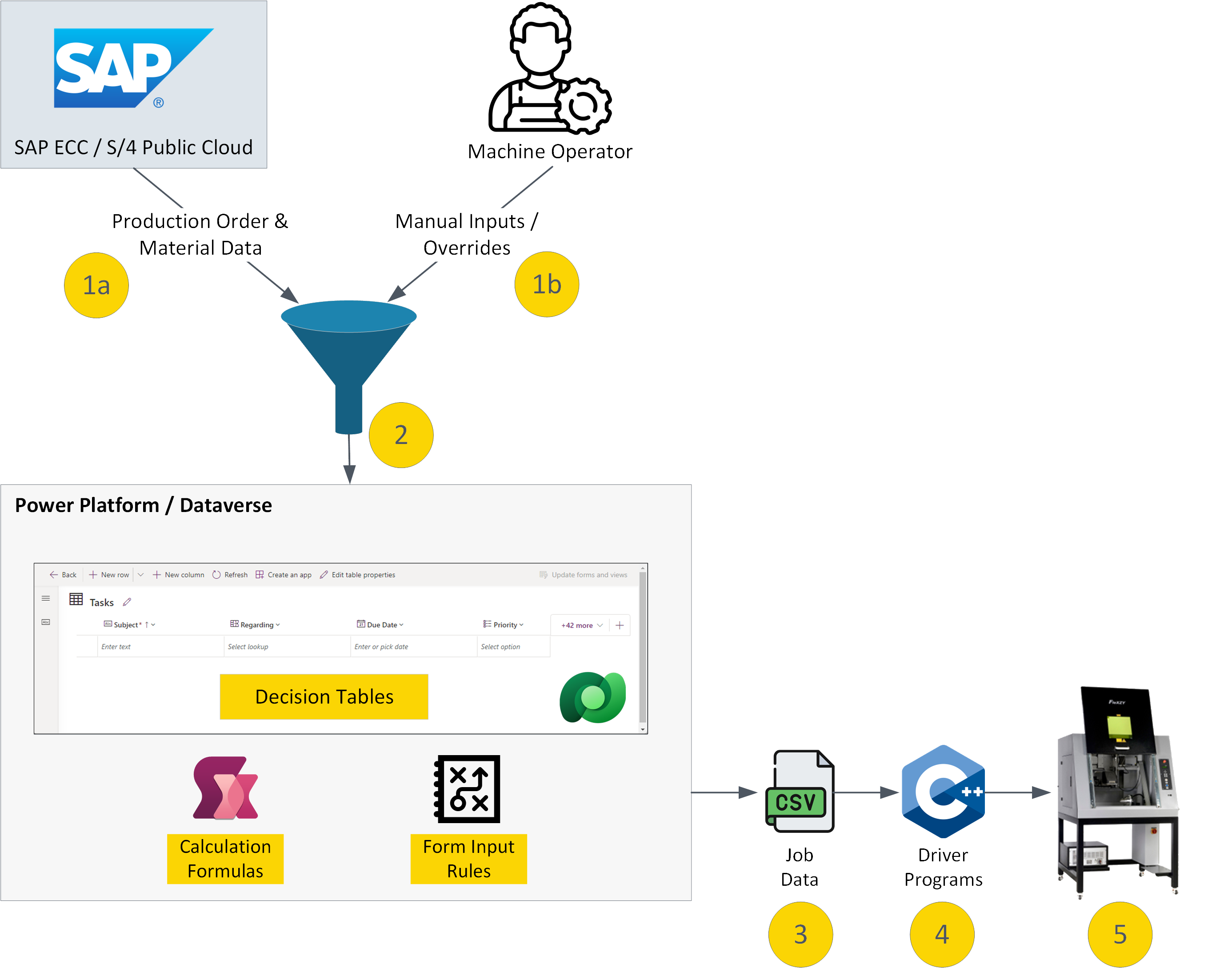

Figure 3: Building an Integration Hub

At the core of Power Automate’s capabilities is its expansive library of over 1,300 prebuilt connectors. These connectors make it possible to integrate with a wide range of applications and systems, including popular ERP platforms like SAP, Oracle, and Dynamics 365. By leveraging these connectors, we can coordinate activities between ERP systems and other components in the production workflow, such as MES systems, IoT devices, and legacy equipment—more on this a little bit later.

Of course, this integration hub doesn’t just stop at data flow. Power Automate also enables full-scale process automation by triggering actions and workflows based on real-time events. For example, when a production order is released in SAP, Power Automate can automatically respond by notifying operators, updating schedules, and initiating machine tasks—all without the need for manual intervention.

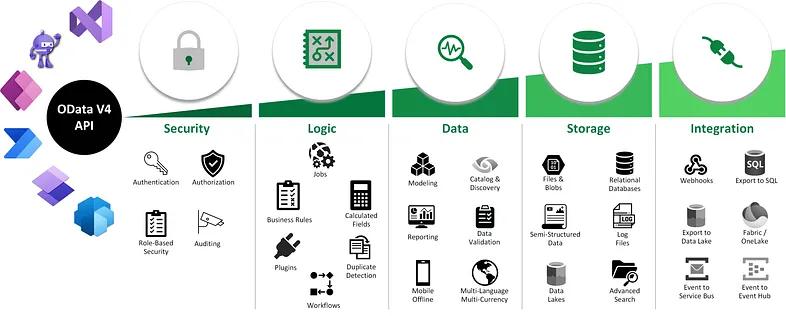

Centralized Business Rules

Building on the Power Automate-based integration hub, we can take our solution to the next level by pairing it with a centralized rules engine powered by Microsoft Dataverse. While the integration hub promotes seamless connectivity and data flow across systems, Dataverse provides the foundation for defining and enforcing the business rules that drive consistency and accuracy in manufacturing processes.

Figure 4: Building a Centralized Rules Engine with Dataverse

Some specific types of rules we can codify within a rules engine like this include the following:

Formulas for calculating dimensions and measurements

Routing rules & task sequencing

Resource scheduling

Job parameter determination

Form field calculations for RPA integration

By integrating a Dataverse-based rules engine into the solution, we can standardize how tasks are processed, calculations are performed, and decisions are made—creating smarter, more reliable workflow processes.

Intelligent Task Routing

As you might expect, one of the real strengths of the Power Platform is its deep integration with collaboration tools like Microsoft Outlook and Teams. Getting back to the concept of delivering work into the hands of the right people at the right time, these features present several powerful capabilities that can go a long way towards making our automation solutions more intelligent and user-friendly:

With our ability to read technician's calendars in Outlook (or status in Teams), we can intelligently (re)route tasks where appropriate.

We can notify technicians of task assignments in Teams.

If there's a problem on the shop floor, we can send an alert and/or escalate the issue to key stakeholders.

We can leverage Microsoft Copilot to embed intelligent bots in Teams that can be used to help shop floor technicians with common problems.

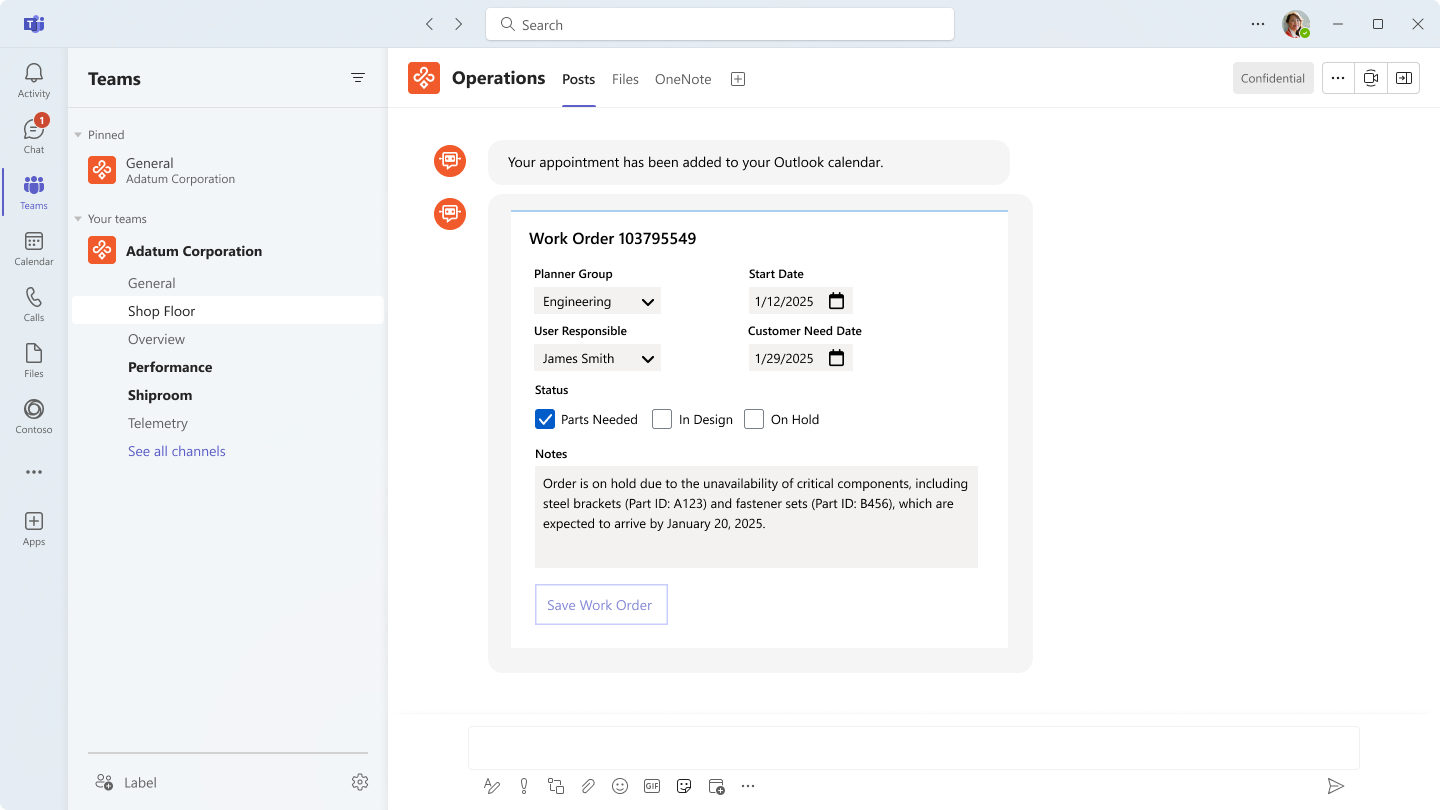

Figure 5 illustrates how all this can come together in a bot experience inside Teams. Here, you can see that the bot has access to the technician's calendar and can perform various tasks automagically where needed. In the bottom section, you can also see where we've embedded an adaptive card that contains a work order form. You can think of these adaptive cards as being like mini-apps that make it easy for various stakeholders to jump in and respond to an issue without having to drop what they're doing and go log onto various ERP or shop floor systems.

Figure 5: Processing Alerts in Microsoft Teams

Integration with Shop Floor Equipment

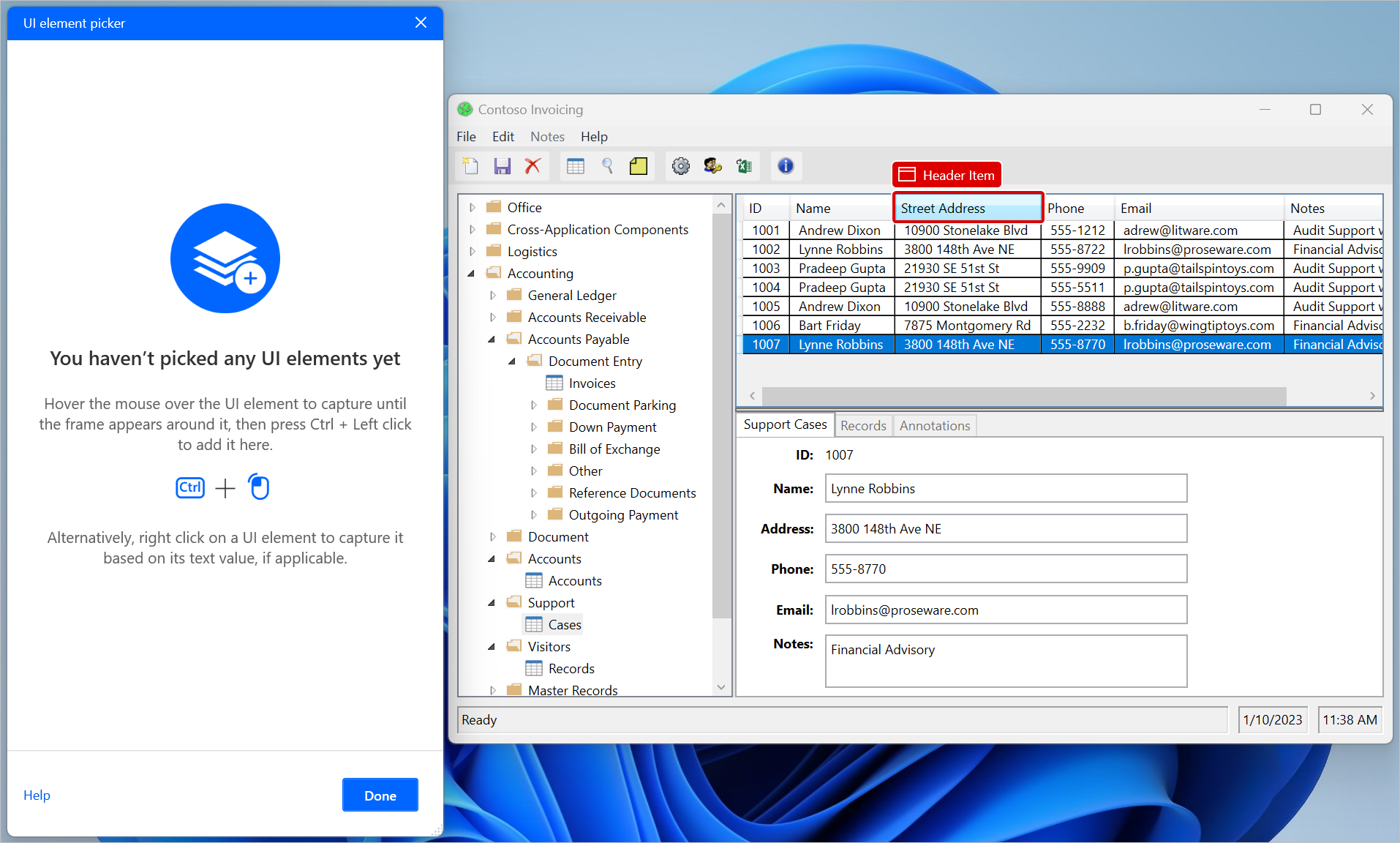

The biggest challenge we face when building automation solutions is figuring out how to integrate with (legacy) equipment that don't support API-based integration. Most of the time, the only way to connect to these systems is through proprietary software applications provided by the manufacturer. Here, we're talking about client applications such as Windows GUI apps, embedded web apps, or terminal applications.

In these situations, we basically have two different options for connecting with these systems:

We can try to surgically enhance (or wrap) the proprietary client applications that communicate with the shop floor equipment.

We can innovate around the edges by creating robotic process automation (RPA) scripts (or bots) that control and orchestrate the execution of transactions within these software packages, automating tasks such as data entry, job execution, and so forth.

Though option #1 may seem like the most elegant approach, the cost/effort to build solutions like this are usually prohibitive—and that's assuming you can find expert developers that can navigate outdated programs that may no longer be supported by the equipment manufacturer. In our experience, RPA solutions based on tools like Microsoft Power Automate Desktop offer a much more flexible and affordable way to bridge these gaps, enabling seamless automation of transaction processing across a variety of application types.

Here, we can create bots that interact with industrial control software just like a human operator would. These bots can navigate user interfaces, input data, click buttons, and retrieve results from applications that lack modern APIs. Whether it’s keying in production order details into a legacy Windows application, issuing commands to a console-based system, or performing data extraction from a terminal emulator connected to a mainframe, RPA bots provide a powerful way to automate repetitive and time-consuming tasks.

Figure 6: Building Desktop App Automations in Power Automate Desktop

Another key benefit of using Power Automate Desktop is that it enables us to orchestrate bot execution using Power Automate cloud flows. This allows for seamless end-to-end automation of production processes, combining API-based integration with ERP and shop floor systems for real-time data exchange, while desktop flows handle tasks on the shop floor by interacting directly with legacy or proprietary software. Together, cloud and desktop flows create a unified automation framework that ensures smooth coordination across systems, tasks, and teams, driving efficiency and reducing manual effort throughout the production lifecycle.

As shown in Figure 7, the driving force behind our automation solution is the aforementioned Dataverse-based rules engine. By connecting RPA bots to this centralized repository of business rules, we ensure they operate with precision and consistency across workflows. The rules engine can dynamically provide instructions for tasks such as data validation, machine configurations, or task prioritization, tailoring operations to the specific requirements of each production scenario. This integration of RPA and intelligent rules transforms task-specific bots into highly adaptable automation tools, capable of managing even the most complex workflows with efficiency and reliability.

Figure 7: Building an End-to-End Automation Flow

Besides eliminating inefficiencies, one of the key benefits to this low-code approach is that it enables you to extend the lifespan of legacy systems by building affordable interfaces that are easy to maintain. Paired with a rules-driven approach powered by Dataverse, we can create smarter, more integrated production processes that can grow with your business.

Continuous Improvement

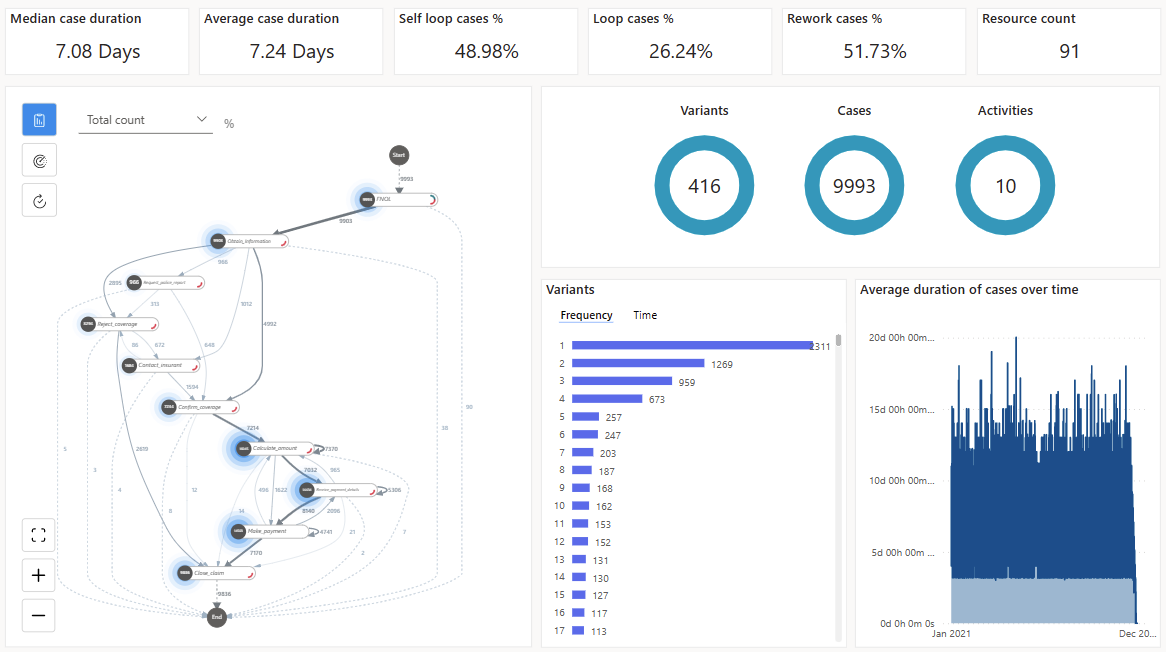

One of the hidden benefits of building industrial automation solutions on Power Automate and Dataverse is that we're able to capture and analyze detailed information about every step in the production process. Unlike traditional approaches, where data collection is often sporadic or limited to specific checkpoints, this style of automation facilitates granular tracking of production steps, task completion times, and machine performance. This wealth of data provides us with unprecedented visibility into operational performance, laying the groundwork for continuous improvement.

With this data centralized in Dataverse, it becomes easier to generate insightful operational reports using Power BI. Dashboards can display key metrics such as task efficiency, machine utilization, or error rates, giving stakeholders the ability to monitor performance in real time and make data-driven decisions. For example, if a particular machine or process consistently causes delays, the data will highlight the issue, enabling proactive interventions to improve efficiency.

Figure 8: Measuring Operational Performance Using Process Mining and Power BI

Beyond reporting, the detailed data captured by automation workflows can be fed into advanced tools like Power Automate Process Mining. This tool analyzes process flows to identify bottlenecks, inefficiencies, or areas for improvement. By visualizing the actual workflows as they occur, manufacturers can pinpoint exactly where delays happen or resources are underutilized. This insight empowers teams to refine workflows, adjust business rules, and eliminate inefficiencies, driving operational excellence over time.

By combining automation with robust data analysis capabilities, you can not only streamline current processes but also create a feedback loop for ongoing improvement. This approach ensures that operations remain agile, efficient, and aligned with evolving business goals.

Closing Thoughts

Hopefully our little demonstration here today has shown you that industrial automation is no longer a luxury reserved for large enterprises with unlimited resources. With tools like Microsoft Power Automate, Dataverse, and Power Automate Desktop, it's never been easier to streamline production processes, bridge the gap between legacy systems and modern technology, and unlock the full potential of your production capacity—all without breaking the bank.

We'll have more to say on these topics in the weeks to come, so stay tuned!